Fusion Implants

The company – formed as a spin-out from the University of Liverpool and consisting of engineers, scientists and orthopaedic veterinary surgeons – would like to further expand on a range of additive manufactured implants for common orthopaedic problems in companion animals. Dan Jones, Managing Director of Fusion Implants, said: “We are excited to take advantage of the Made Smarter business support program. The program will aid research and development for Fusion Implants, whilst also giving a recent graduate an opportunity to develop skills in additive manufacturing and in implant design and development. Our end goal for the Made Smarter program is to have a prototype product and a new employee.”

Abbey Group

Abbey Group, based on the Knowsley Industrial Estate, provides a broad range of engineering solutions to UK industry in the automotive, rail, security, warehousing, energy and structural steel sectors. It wants to invest in digital technologies – system integration, data acquisition and AI – to introduce real-time machine monitoring on the factory floor to capture live data and report on potential manufacturing efficiencies and costs.

Chris Jones, Managing Director of Abbey Group, said: “Investing in digital technologies will truly transform our current business, increasing profitability – while remaining highly competitive – and productivity, while allowing us to develop innovative products in-house that will drive growth and sustainability and facilitate further diversification of our product portfolio.”

Applied Nutrition

Applied Nutrition, based in Knowsley, designs and manufactures diet and exercise supplements for athletes. It wants to speed up production and improve its stock management, freeing up staff to focus on other areas of the business. Working with Made Smarter it has identified opportunities to innovate using robotics and process control automation, IIoT, Data and Systems Integration, Big Data and Analytics.

Thomas Ryder, Managing Director, said the new technology will boost productivity, open new markets, upskill the current workforce and create new jobs. “By working with Made Smarter we have identified an excellent opportunity to improve our manufacturing facility using digital technologies,” he said. “It will enable us to package our products up to eight times faster – vastly increasing our productivity. It will also enable us to handle data and stock more effectively and accurately allowing us to monitor our production in real-time. The benefits to this are massive as it will allow us to have much more control over production and focus on larger orders, as well as contribute to our local and national economy.”

The Nursery Kitchen

The Nursery Kitchen in Birkenhead is a food manufacturer which produces 15,000 meals per week to nurseries across the UK. It wants to introduce automation, data acquisition, analytics and IoT technologies to move from out-dated, manual paper-based processes to a more automated and integrated resource planning, stock control and client ordering system. This will allow the company to reduce its administrative burden, minimise errors, boost its productivity and comply with increasingly stringent food safety standards.

Jane Gordon, Sales and Marketing manager at The Nursery Kitchen, said the new system will enable the business to take on more staff, expand its customer base and launch new ranges. “From cottage industry caterer to food manufacturer, our business has become a victim of its own rapid success,” she said.

“We recognise that the barrier to more efficient processes and controls, as well as growth and increased productivity, is an absence of integrated digital technologies. The Made Smarter support programme has come along at a crucial moment for the Nursery Kitchen and will help secure its future.”

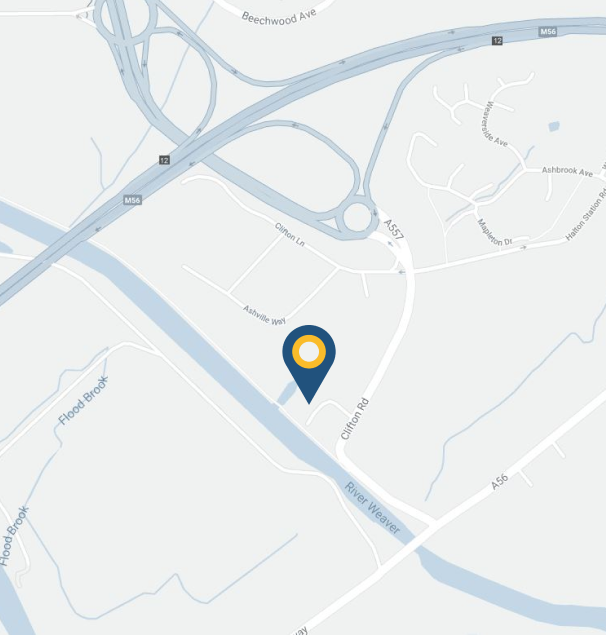

DT Engineering

DT Engineering North West Ltd, a specialist manufacturer of crane and lifting equipment based at Everite Road Industrial Estate in Widnes, wants to incorporate digital technologies into heavy engineering environments to ensure the safe operation of potentially dangerous equipment. Tom Coyle, Managing Director, said the project with Made Smarter will create new jobs and boost sales opportunities. “Success of this project will completely transform our business, allowing the company to grow and become far more profitable as we anticipate the integration of digital technologies and systems to complement our current core business,” he said.

Donna Edwards, Director of the Made Smarter North West pilot, said: “I am delighted that the Made Smarter pilot has now supported the first successful SME applications, including Abbey Group, Applied Nutrition, Fusion Implants, The Nursery Kitchen and DT Engineering North West. We have found businesses are enthusiastic about the benefits of adopting new digital technology. Often, they need funding support, alongside specialist advice and insight to help them select the right approach for their business. This is exactly how Made Smarter can and is helping businesses across the Liverpool City Region. Made Smarter is relevant for any North West SMEs who make, create, manufacture or engineer, and I urge local businesses not to miss this opportunity. I would encourage anyone who may be interested to register today for a fully-funded audit of your operations and see how Made Smarter might be able to help you.”